Adiabatic cooling air/air solutions for data centers

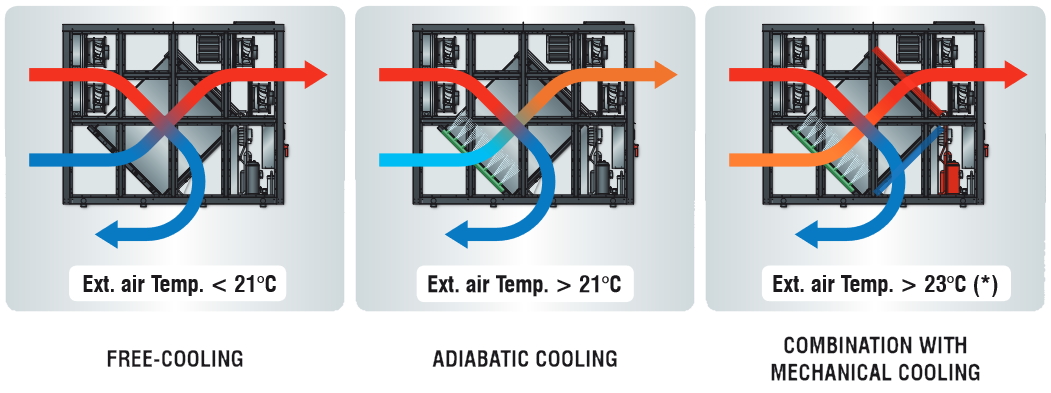

The indirect Free Cooling of DataBatic units can be extended to a greater number of hours per year and to more climatic zones thanks to the combination of the Evaporative Cooling system and of the air-to-air cross-flow heat exchanger. The decrease (and in some cases the cancellation) of the mechanical operation thus leads to a twofold benefit: the reduction of running costs (lower PUE levels) and the reduction of implementation costs thanks to lower installed electrical powers.The HDB units can be equipped with the “refrigerating circuit option” and are fully factory assembled in a one-piece solution to facilitate the installation.

Since the power consumption of the cooling system represents a significant part of the total energy consumption of a data center, improving the energy efficiency of such rooms inevitably involves optimizing the cooling system.

Characteristics of HDB units:

- It does not create contamination of the air inside the server room with the outside air

- Compact design (monoblock)

- Low PUE and WUE

- Water saving function and legionella-free system

Evaporative cooling on the intake air stream

DataBatic units are equipped with the Evaporative Cooling technology, based on the use of nozzles which atomize water on the air stream flowing from outside. The water evaporates and cools the air thanks to the adiabatic effect. The air then flows through the cross-flow heat exchanger at a temperature close to the wet bulb temperature, extending Free-Cooling mode operating time. The system, finally, is of multistep type with respect to the air flow so as to optimize the saturation efficiency.

DataBatic units are equipped with the Evaporative Cooling technology, based on the use of nozzles which atomize water on the air stream flowing from outside. The water evaporates and cools the air thanks to the adiabatic effect. The air then flows through the cross-flow heat exchanger at a temperature close to the wet bulb temperature, extending Free-Cooling mode operating time. The system, finally, is of multistep type with respect to the air flow so as to optimize the saturation efficiency.

Chilled water or direct expansion integration

(*) Wet bulb conditions for a 1 MW Data Center (N + 1 redundancy) in Amsterdam