Testing Labs and factory acceptance tests

FATs (Factory Acceptance Tests) are part of HiRef testing process. These let end customers or their technical consultants personally ascertain that the equipment complies with project specifications. Temperature, pressure, flow, and vibration transducers are connected to a monitoring computer that provides readings of the product’s operating parameters, for a complete performance assessment. The data gathered are used to calculate different performance indicators and assess efficiency, energy savings and any other parameter for satisfying project requirements.

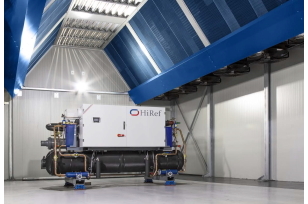

Hyper Lab

The Hyper Lab, newly developed entirely by the in-house HiRef R&D department, is designed for testing and acceptance of the following machines:

- Chiller

- Heat pump

- Air/air units for Data Centers with adiabatic system

- Maximum testable

- up to 1.5 MW cooling capacity

- up to 2.0 MW heating capacity

For air-to-air units, the lab can simulate an external environment (outside air intake) with temperatures as low as -35 °C. Hyper Lab can recreate the desired operating conditions under Free-Cooling mode, in other words, drawing air directly from the outside of the building and conveying it to the climatic room through a system of ducts and motor-driven dampers.

Like the other HiRef labs, Hyper Lab is equipped with a sophisticated data acquisition and supervision system that offers real-time monitoring of the following parameters:

- Air temperature and humidity

- Water temperatures

- Pressure drops at water or air side

- Operating pressures and temperatures of refrigeration circuit

- Flow rates of processed fluids

- Electrical measurements and every derived power and efficiency measurement

Data Centre Lab

Data Centre Lab is a climatic laboratory with raised floor and false ceiling used to replicate different server room layouts. The infrastructure enables us to test direct expansion or chilled water units and allows for reversible and multi-directional airflow inside the room to adapt to different test configurations. With the Data Centre Lab we can exactly reproduce actual operating conditions to test CRAC units with Upflow, Downflow or Displacement configuration.

The Data Centre Lab is made up of two rooms, separated by an insulated partition wall that can be removed, if necessary. The two rooms can operate independently, recreating two environments with different climate conditions (an internal and external environment, for example), or they can be kept at the same temperature and humidity conditions to simulate one confined space. The Data Centre Lab is also designed and ready for sound intensity testing of CRAC units under operating conditions and for performance tests of air-to-water and water-to-water chillers up to 400 kW chilling capacity.

LowT Lab

The LowT Lab is a climatic room used to recreate extreme temperature conditions (as low as -50 °C), simulating the coldest winter climates. This makes it possible to test monobloc telecom air conditioners; components such as test units, fans, and electrical panels; and reduced-scale prototypes. To maintain critical temperature conditions, the room uses direct expansion units connected to a two-stage compressor with sub-critical CO2 refrigeration cycle.

The primary purpose of the LowT Lab is to test components that will be installed in very cold climates for proper functioning. It is crucial, in fact, to rule out freezing of individual parts and risks for the machine when starting up or running continuously in cold temperature conditions.

Acoustic tests in outdoor area

Particularly important is the measurement of sound emissions, for which HiRef provides an outdoor area certified according to UNI EN ISO 3746. Thanks to the collaboration with the University of Padua, HiRef can draw on the expertise of academics for the certification of acoustic tests performed in an off-site qualified area compliant with the UNI EN ISO 3746 standard. Class 1 instruments are used, providing an accuracy of 1.5 dBA under favourable environmental conditions.